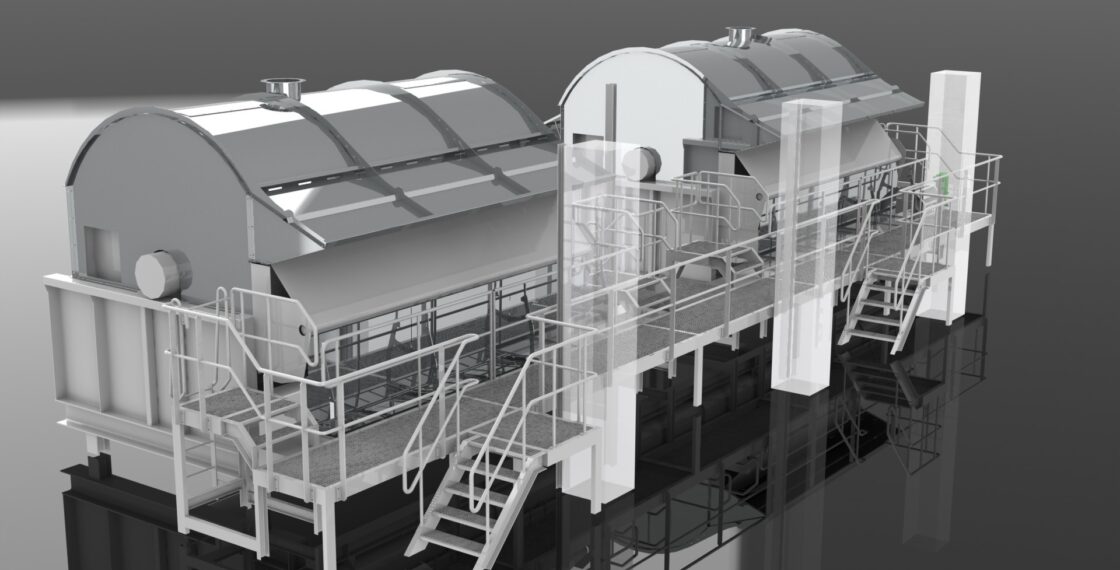

Each filter hood is 5700 x 3500 x 2300 mm in size and made of 316L stainless steel, which meets the strict requirements of the food industry. Type 316L stainless steel has a very low carbon content, resulting in a stainless steel that is easy to weld and retains its corrosion resistance after welding. This makes it extremely suitable for application in a corrosive environment as is often the case in food industry.

The vacuum filter consists of a trough and a rotating drum with a filter cloth. The gluten mixture is pulled on to the filter cloth by the vacuum on the inside of the drum and the water is removed when the drum rotates. On the other side of the drum, the gluten ‘cake’ is transported to the second stage of the drying process: the ‘flash dryer’. In 2009, Feyer Industrial Services fully converted this flash dryer from a corn fibre dryer into a corn gluten dryer.